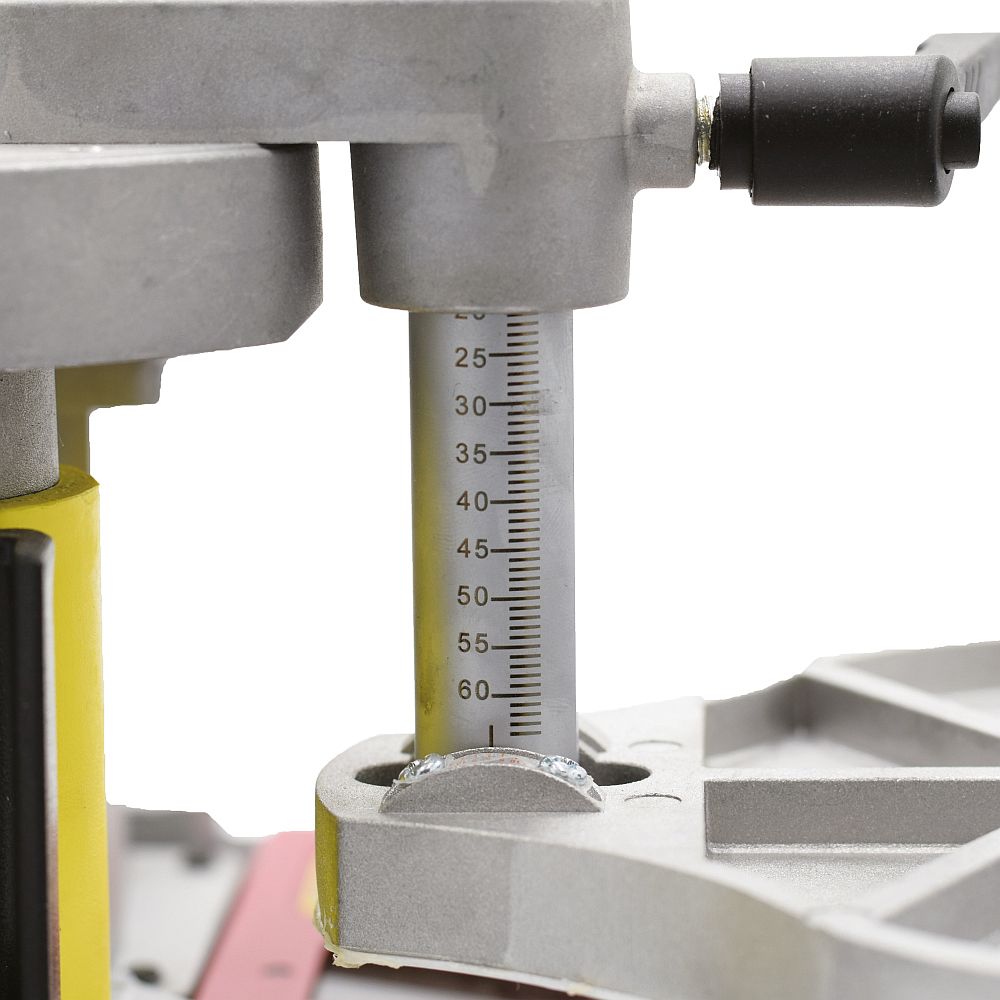

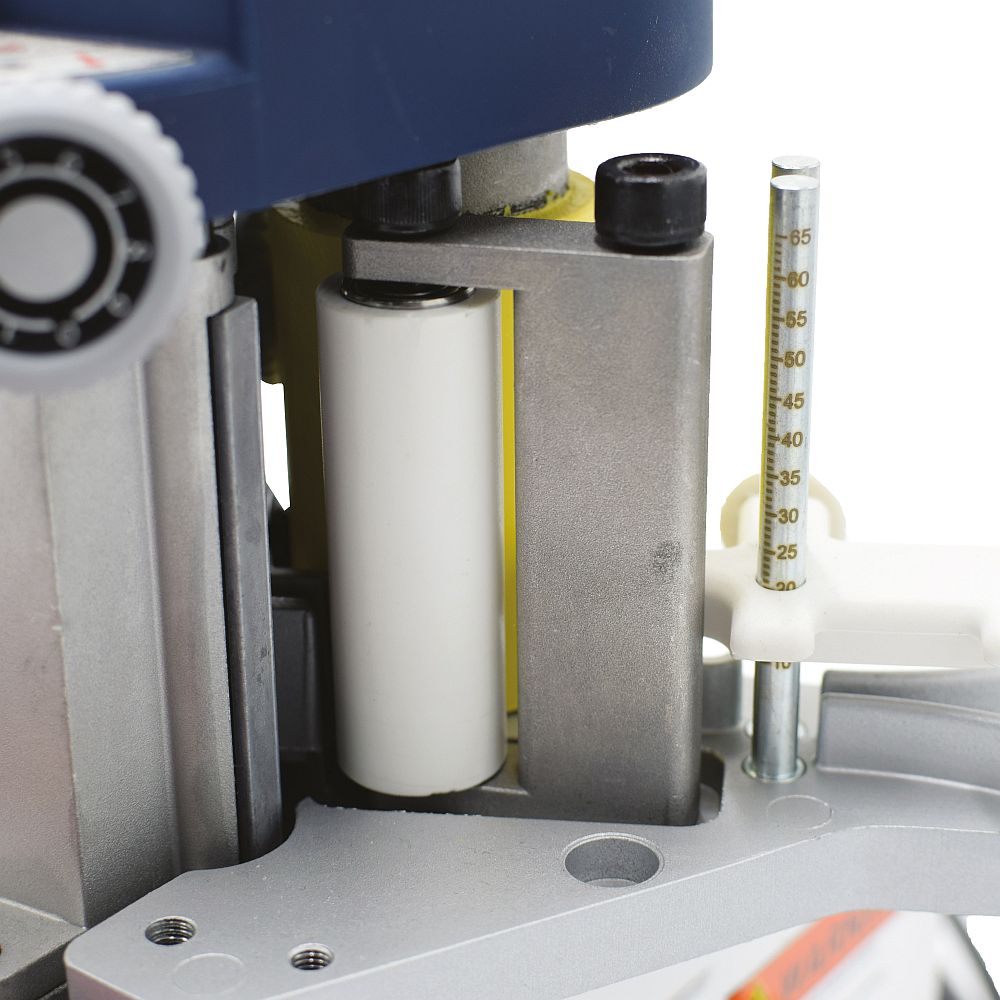

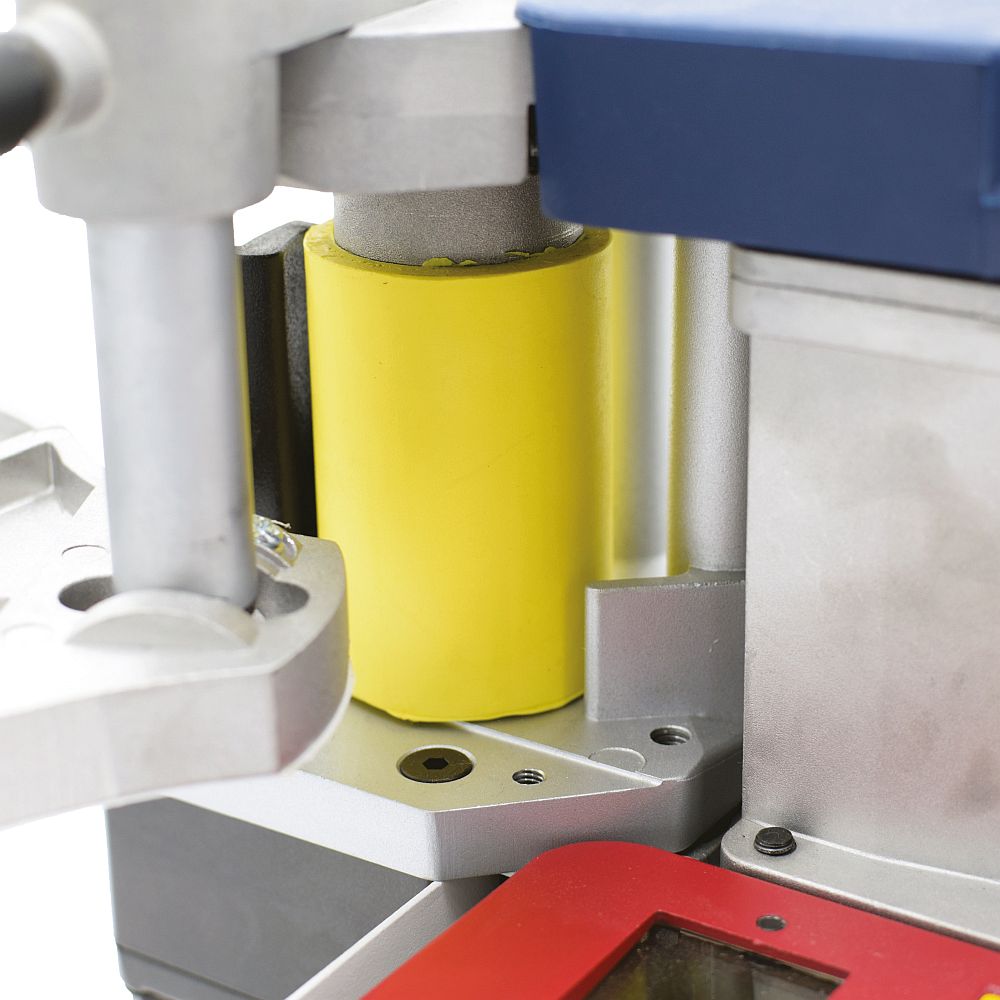

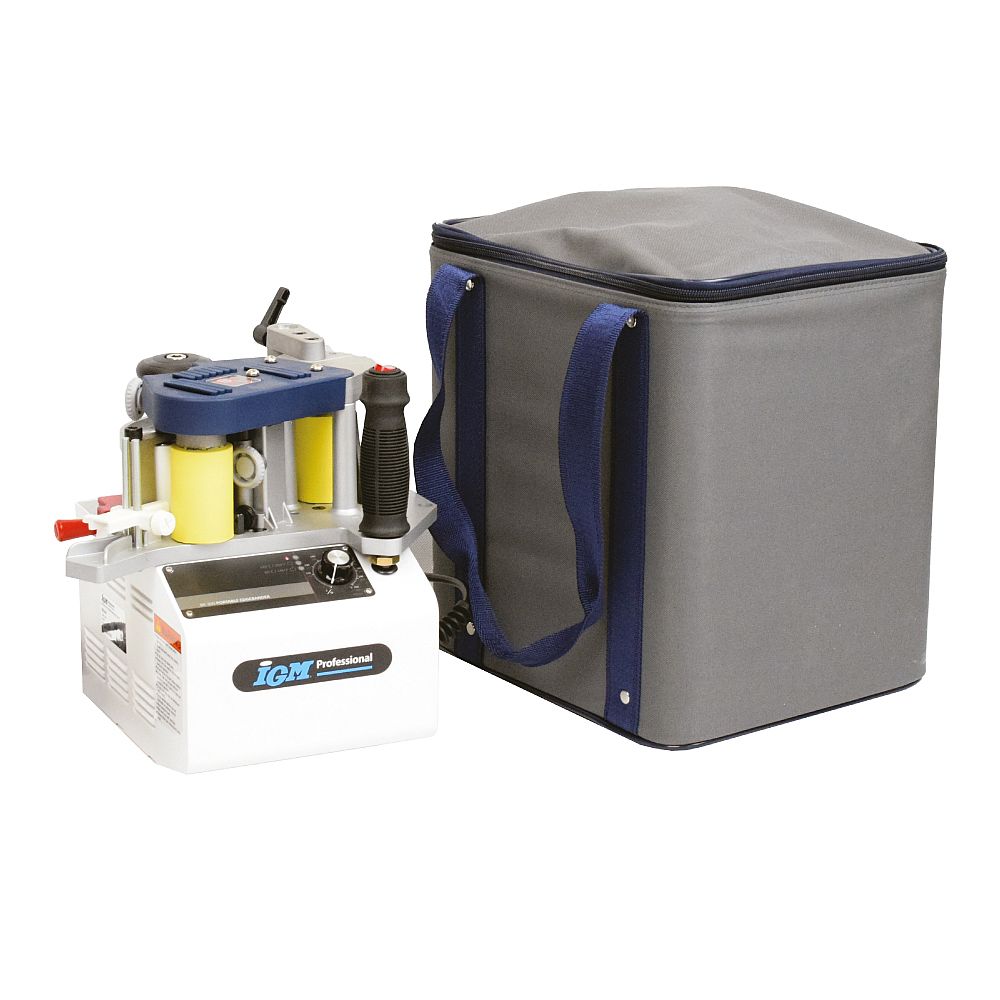

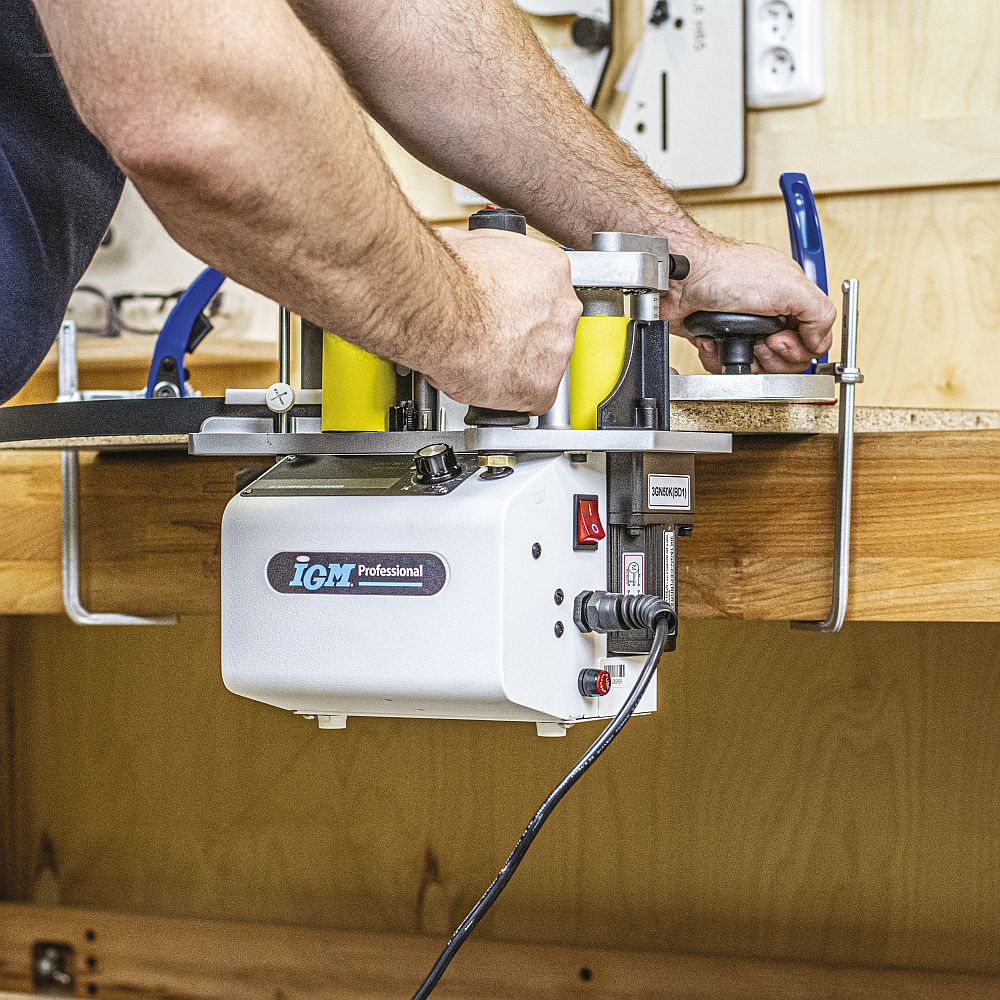

– Bandning av upp till 3 mm tjocka möbelkanter ABS, PVC, remsor eller fanér. – Innovativt limappliceringssystem, överträffar dubbel applicering. – Fasta och rent limmade kanter med minimalt överflöd. – Raka och formade arbetsstycken upp till 65 mm tjocka. – Kantlimning i +/-15° vinkel. – Stabil styrning av det släta stödbordet med skala för inställning av arbetsstyckets tjocklek. – Förbättrad funktion för inre hörnbandning. – Justerbar temperatur och jämn matningshastighet. – Mycket snabb uppvärmning till arbetstemperatur. – Lätt att hantera och enkel att använda. Ett nytt revolutionerande sortiment av toppmoderna IGM-kantlistermaskiner med smältlim är konstruerade för snabb kantlistning av 0,4 – 3 mm tjocka ABS-, PVC-, laminerade möbelkanter eller faner, på raka eller formade arbetsstycken med en tjocklek från 10 mm till 65 mm. Det granulära limmet smälts snabbt i en smältkammare och appliceras genom ett nytt sofistikerat system på tejpen, som pressas perfekt mot arbetsstycket med gummerade rullar. Tejpen fäster stadigt och helt på den bandade kanten, vilket resulterar i en fast och ren bindning längs hela tejpens bredd. Den nya generationens IGM-kantlistmaskiner har många unika och patenterade funktioner som du inte hittar någon annanstans. Alla delar i kantlimmaren är exakt bearbetade och noggrant monterade. Detta garanterar en fast och ren limning av möbelkanterna och en tejp med minimalt överflöde. Den nya generationens snabbuppvärmningssystem smälter limmet på 5 minuter från start. Dessutom håller termostaten maskinen i drift om du fyller på lim i en halvfull tank. Kantlimningsmaskinen har en jämn applicering av lim, som enkelt kan regleras med styrenheten. Det innovativa limappliceringssystemet, som är bättre än dubbelapplicering, applicerar limmet exakt och jämnt på tejpen utan att hoppa över, rinna över eller förorena maskinen. Tejpen styrs exakt genom en justerbar breddmätare (upplösning 1 mm), vilket möjliggör exakt och problemfri styrning av tejpen mot den cylindriska tejpappliceraren. Två gummerade ergonomiska handtag möjliggör exakt styrning av maskinen längs arbetsstycket. Stödbordet har ett speciellt halkskikt som möjliggör enklare matning utan att repa arbetsstycket. Det är också försett med en skala för exakt justering av arbetsstyckets tjocklek och placeras i en solid hållare med möjlighet till +/-15° lutning, vilket möjliggör exakt kantlistning av fasade ytor. Lockhandtaget kan placeras i två lägen beroende på typ av bandning. BR300 kantlistmaskin är utrustad med en manuell temperaturreglering, placerad horisontellt, för full kontroll över bandningsprocessen. Exakt inställning av önskad temperatur. Temperaturområde 120 – 200°C ± 1°C. Konstant matningshastighet 4,0 m/min, idealisk för vanliga krav på kantlistning av böjda eller formade delar. Det är en lätt, praktisk och enkel maskin att använda, idealisk för arbeten ute på fältet eller i verkstaden, kan spännas fast i ett arbetsbord. Idealisk för arbete ute på fältet eller i verkstaden som stationär maskin. Typ: BR300 Klassning: Professionell Effekt: 855 W ( 230 V) Kanttjocklek: 0,4 – 3 mm Kanthöjd: 10-65 mm Fasytor: 75°- 90° Min. Inre arbetsstycksradie: 25 mm Matningshastighet: 4 m/min. Justerbar temperatur: 100 – 200°C Rekommenderad smälttemperatur: 140°C Kapacitet limbehållare: 400 ml Längd x Bredd x Höjd: 340 x 300 x 350 mm Vikt: 8,7 kg Levereras med: – Hörnguide – Demonstrationsexemplar av limmad tejp – Instruktioner Förpackad i en lätt låda för säker transport

IGM 198 Upcut Spiral Frässtål HWM Z1 - D6x22 L60 S=6

481 kr Inkl. Moms

IGM 198 Upcut Spiral Frässtål HWM Z1 - D6x22 L60 S=6

481 kr Inkl. Moms

IGM Sliphylsa D50,8x230mm - 80G

330 kr Inkl. Moms

IGM Sliphylsa D50,8x230mm - 80G

330 kr Inkl. Moms

IGM BR300 Portabel Kantlimmare

17064 kr Inkl. Moms

Onlinelager:

I lager

– 10+ st

Rekommenderat tillbehör

Ytterligare information

| Vikt | 11 kg |

|---|---|

| Dimensioner | 340 × 310 × 370 cm |