Liten 3-axlig 2D- och 3D CNC-router IGM i2R A24 för trä, plast och metall, med en 2200 W spindel och ett arbetsområde på 610 x 1220 mm. Enkel styrning via UCCNC-programvara och närhetssensorer för exakt axelkalibrering.

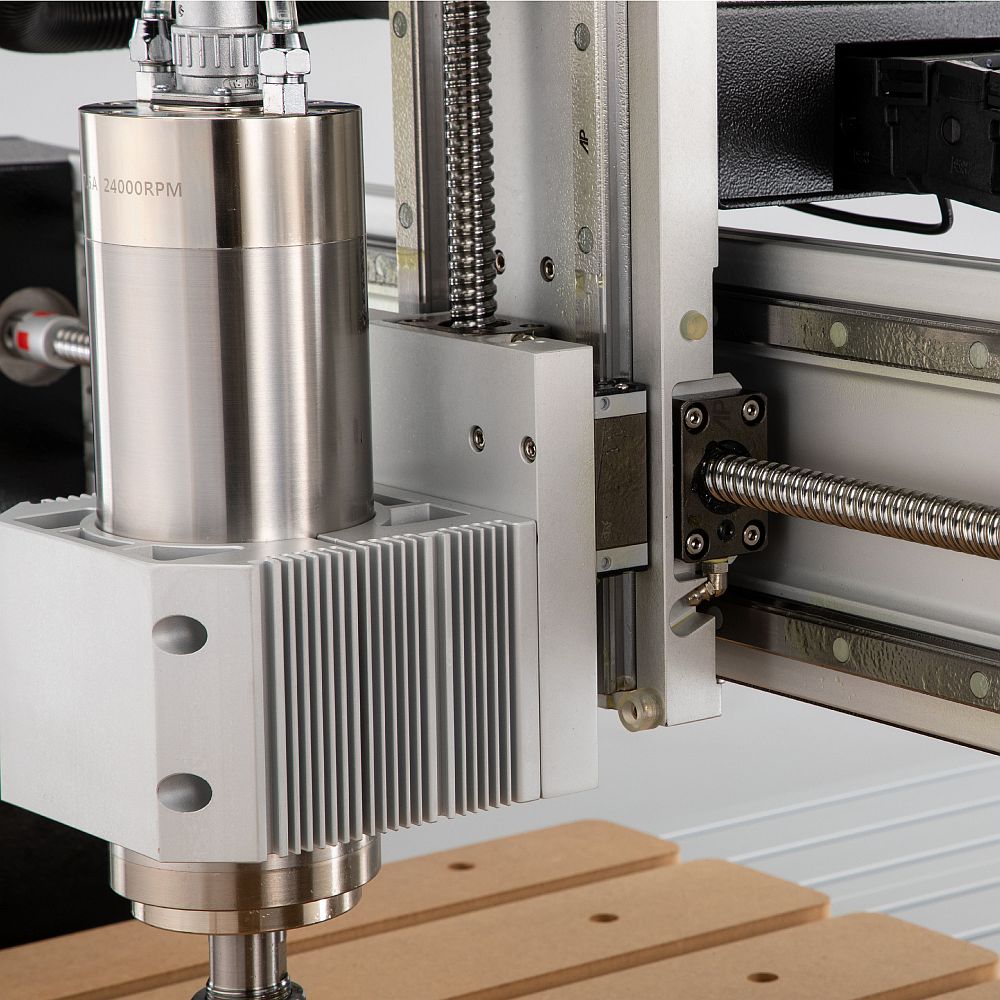

– Vätskekyld spindel på 2,2 kW.

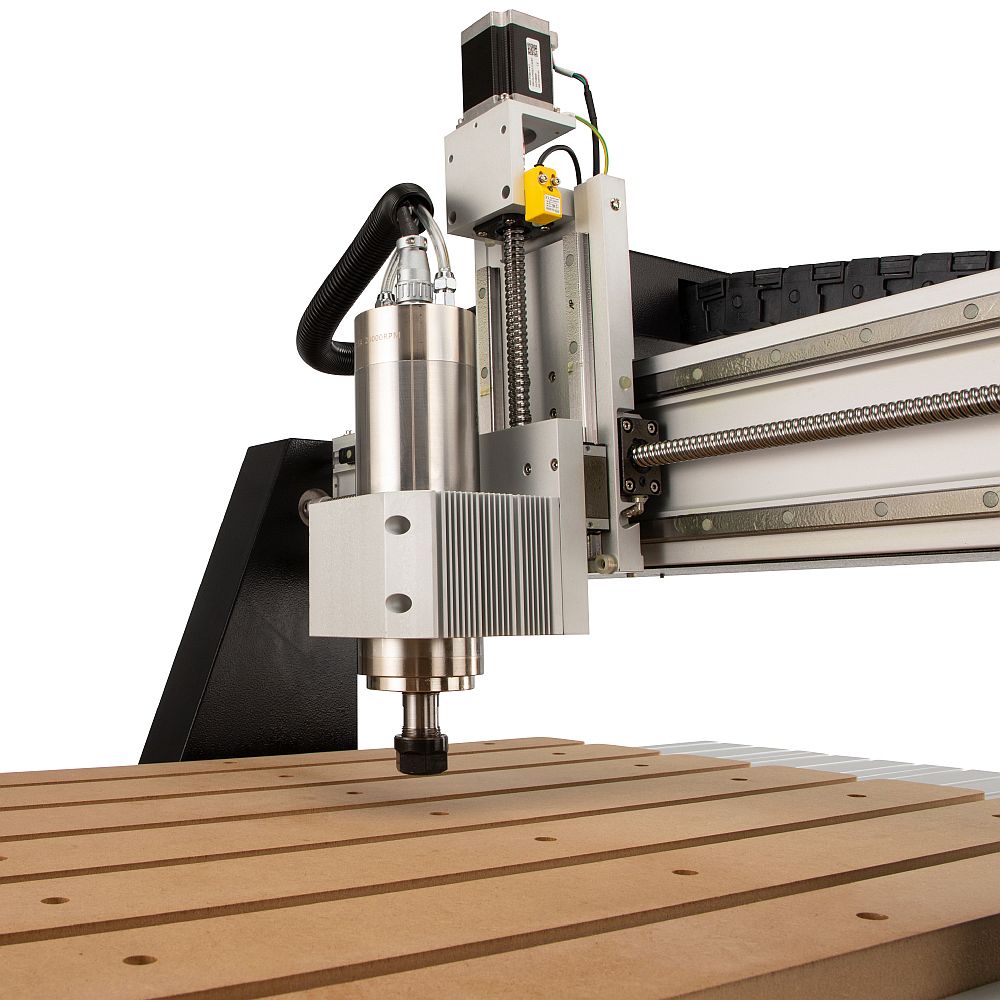

– Spindelns rörelseområde 610 x 1220 x 150 mm (X x Y x Z).

– Kulskruvar med hög precision.

– Prismatiska styrskenor på varje axel.

– Integrerad magnetisk sensor på varje axel.

– Touchsensor för Z-axeln.

– Exakt och plan aluminiumbordsskiva med T-spår och MDF-skivor.

– 2D- och 3D-bearbetning.

– Enkel maskinstyrning med PC och 3D-projektvisualisering i realtid.

– Upprepningsnoggrannhet 0,05 mm.

CNC-routern IGM i2R A-series är en av de bästa CNC-routrarna i litet format på marknaden och kombinerar precision, hög prestanda, lång livslängd, användarvänlighet och underhållning i ett. Routern är utvecklad för både hobbyanvändare, småföretagare och proffs och kan uppgraderas med många funktioner, t.ex. en rotationsenhet för 4:e axelbearbetning. Routern styrs på en Windows-dator via UCCNC-programvaran, ett mycket intuitivt gränssnitt med många alternativ som är praktiska även för nya eller oerfarna CNC-operatörer.

IGM i2R A-series CNC Router kan bearbeta alla träbaserade material, skum, polystyren, mässing och aluminium. Utformad för 2D-skärning av möbeldelar, intarsia, 3D-modeller, skulpturer, prover och prototyper eller för märkning och etikettering.

A24 har extremt exakt rörelse på 16 mm kulskruvar och högkvalitativa prismatiska styrskenor med låg friktion på varje axel. Av denna anledning finns det inga drivremmar eller växellådor som skulle minska precisionen och orsaka vibrationer. Både kulskruvarna och styrskenorna är försedda med recirkulationslager som klarar höga belastningar i alla riktningar samtidigt som de ger mycket lågt spel och oöverträffad noggrannhet.

I stället för den vanliga luftkylda spindeln har i2R A-serien en kraftfull vätskekyld spindel på 2200 W, vilket ökar livslängden och framför allt prestandan. Det högpresterande kylsystemet i kombination med kraftfulla stegmotorer med högt vridmoment säkerställer att maskinen kan arbeta kontinuerligt hela dagen utan avbrott.

En solid, svetsad stålram bär upp en massiv, 40 mm tjock aluminiumbordsskiva med integrerade MDF-skivor som håller arbetsstycket i perfekt nivå och skyddar dina verktyg och bordsskivan från skador vid kapning. Det finns T-spår mellan MDF-skivorna för montering av klämmor och andra tillbehör som t.ex. en dammarm eller en 4:e axel rotationsenhet.

Till skillnad från andra konkurrerande maskiner är CNC-routern i2R utrustad med magnetiska närhetssensorer på varje axel för att förhindra att gantry stöter emot ändstopp vid gränslägen. Detta gör att man kan använda en HOME-knapp som kalibrerar alla tre axlarna. När kalibreringen är klar vet maskinen exakt var spindeln befinner sig i förhållande till arbetsytan. Alla kablar och kylrör är skyddade från oavsiktlig bortkoppling, skador eller klämning eftersom de är integrerade och omslutna av en flexibel nylonkabelkedja.

Programvaran UCCNC, som levereras med en licens, ger realtidsvisualisering av varje steg i din bärbara dator. Med UCCNC kan du styra CNC-maskinens rörelser och parametrar, mäta verktygshöjden med Z-axelns touchsensor, arbeta med den 4:e axeln och övervaka hur arbetet fortskrider i både en 2D- och 3D-förhandsgranskning. UCCNC:s maximala kompatibilitet med Windows OS gör att du kan styra i2R-routern med en Xbox-kontroller (ingår ej).

UCCNC-programmet styr maskinen, men du måste skapa ditt projekt någon annanstans. Det är här CAD/CAM-programvaran kommer in i bilden. Programvaran exporterar ditt färdiga projekt i G-kod, som enkelt laddas upp till UCCNC med ett klick på en knapp. Sedan är det bara att justera maskinen efter arbetsstycket och börja arbeta. På grund av arbetsområdet för A24-modellen rekommenderar vi att du köper programvaran VCarvePro som gör att du kan skapa projekt på hela arbetsområdet på 610 x 1220 mm. Med VCarveDesktop kan du skapa ditt projekt i ett begränsat arbetsområde på upp till 610 x 610 mm.

Maskinen levereras med en touchsensor för Z-axeln. När du sätter in ett nytt verktyg i spindeln måste du mäta verktygets längd i förhållande till den bearbetade delen eller arbetsytan. Sensorn ansluts helt enkelt till en port på gantry, placeras under verktyget och sedan ställs längden automatiskt in i UCCNC-programmet genom att klicka på AUTO Touch-off-knappen.

Minimikrav för PC eller bärbar dator för UCCNC och Vectric-programvaran:

– Processor: 2 GHz

– RAM: 4 GB

– Lagring: 16 GB

– Operativsystem: Windows 7, 8, 10, 11

– Övrigt: USB-A-port + Ethernet-port

Notebook och Vectric CAD/CAM-programvara ingår inte.

– Typ: i2R A24

– Rekommenderad användning: Hantverk

– Spindel (230V): 2200 W

– Spindelkylning: Vätska

– Spännhylsa typ: ER20

– Spännområde: 1 – 13 mm

– Spindelhastighet: 0 – 24 000 varv/min

– Maxhastighet i X/Y-axel: 6000 mm/min (83 mm/s)

– Maxhastighet i Z-axel: 2000 mm/min (33 mm/s)

– Rörelse: Kulskruv 16 mm + prismatiska styrskenor

– X-axelområde: 610 mm

– Y-axelområde: 1220 mm

– Z-axelområde: 150 mm

– Port för dammuppsamling: 100 mm

– Gränssnitt: UCCNC (PC med Windows OS)

– Maskinmått (LxBxH): 1650 x 950 x 770 mm

– Maskinvikt: 150 kg

– Transportmått (LxBxH): 1670 x 1000 x 840 mm

– Transportvikt: 188 kg

Paketets innehåll:

– CNC-maskin A24 med kontrollbox

– 2x spännhylsa ER20 (8 mm och 12 mm)

– Dammsko

– 2x Skiftnyckel för spindel

– Beröringssensor för Z-axel

– UCCNC-licens (obegränsad)

– 4x nedhållande klämma

– Ethernet-kabel

– Smörjpistol